Irbesartan/Hydrochlorothiazide Carbon Footprint Calculator

Calculate Environmental Impact

Enter the amount of Irbesartan/Hydrochlorothiazide API (Active Pharmaceutical Ingredient) to see the environmental impact and potential improvements.

Every pill you swallow leaves a footprint you can’t see - the manufacturing steps, the solvents, the waste water, the energy use. When it comes to the popular blood‑pressure combo Irbesartan/Hydrochlorothiazide is a fixed‑dose antihypertensive that blends an angiotensin‑II receptor blocker with a thiazide diuretic. It’s prescribed to millions worldwide for better blood‑pressure control. Understanding its environmental impact helps doctors, patients, and manufacturers make greener choices.

Why the Production Process Matters

Drug manufacturing isn’t just about mixing chemicals in a lab; it’s an energy‑intensive, water‑heavy supply chain. From raw‑material extraction to API synthesis, each step generates carbon dioxide, volatile organic compounds (VOCs), and hazardous waste. For a high‑volume drug like Irbesartan/HCTZ, the cumulative effect can be significant.

Key Environmental Hotspots in Irbesartan/HCTZ Manufacturing

- Raw‑material sourcing: The aromatic rings in Irbesartan come from petro‑derived benzene, while Hydrochlorothiazide relies on chlorine‑intensive intermediates.

- Solvent use: Traditional syntheses use large volumes of N‑methyl‑2‑pyrrolidone (NMP) and dichloromethane, both high‑risk solvents.

- Energy consumption: Heating, distillation, and crystallization demand steam and electricity, often powered by fossil fuels.

- Water footprint: Purification steps generate thousands of liters of wastewater per batch.

- Waste management: By‑products include heavy metals and halogenated compounds requiring special treatment.

Quantifying the Impact: Life Cycle Assessment (LCA) Data

Recent LCA studies (2023‑2024) give us a ball‑park view:

| Metric | Irbesartan | Hydrochlorothiazide | Losartan (benchmark) |

|---|---|---|---|

| CO₂‑equivalent (kg) | 12.4 | 8.7 | 10.1 |

| Water use (m³) | 1.9 | 1.2 | 1.5 |

| Solvent waste (kg) | 3.2 | 2.1 | 2.5 |

| Energy demand (MJ) | 58 | 42 | 50 |

These numbers show Irbesartan’s carbon and solvent footprints are higher than Hydrochlorothiazide but comparable to other ARBs like Losartan. The combination product inherits the sum of both, making it a notable target for improvement.

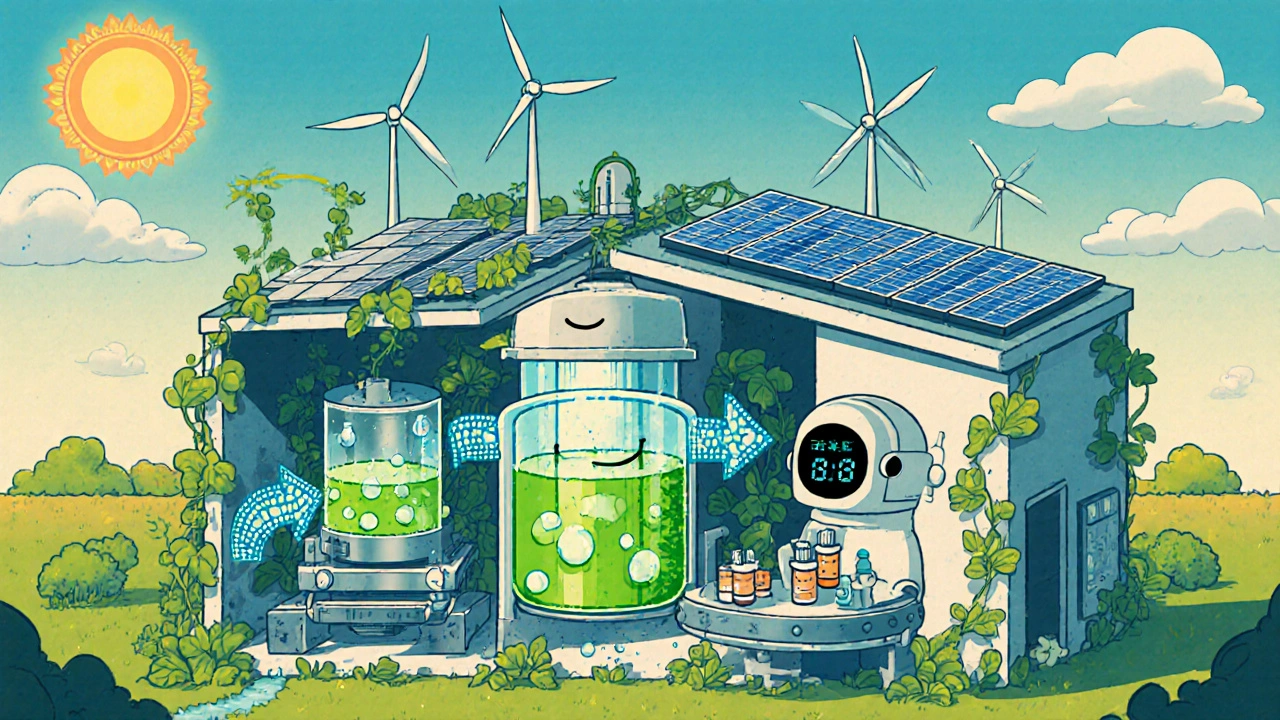

Green Chemistry Strategies to Cut the Footprint

Manufacturers can adopt several proven tactics:

- Solvent substitution: Replace NMP with 2‑methyltetrahydrofuran (2‑MeTHF) or ethanol, which have lower VOC scores and are biodegradable.

- Process intensification: Use continuous flow reactors for Irbesartan synthesis. Flow chemistry reduces batch size, cuts energy use by up to 30 % and improves safety.

- Catalyst recycling: Implement homogeneous palladium catalysts that can be reclaimed via membrane separation, cutting metal waste.

- Water‑reuse loops: Integrate membrane bioreactors to treat and recycle process water, lowering fresh‑water intake.

- Renewable energy integration: Power distillation columns with on‑site solar or wind, turning a high‑energy step greener.

When companies apply at least three of these measures, LCA data suggest up to a 40 % reduction in CO₂‑e and a 35 % drop in solvent waste.

Regulatory Landscape and Reporting Requirements

Globally, agencies are tightening the reins:

- EU EMA: The European Medicines Agency mandates environmental risk assessments (ERAs) for new drug submissions. Irbesartan/HCTZ batches must include data on ecotoxicity and persistence.

- US FDA: The Food and Drug Administration’s Guidance for Industry: Environmental Assessment for Human Drug Products encourages voluntary reporting of carbon footprints.

- WHO: The World Health Organization’s Pharmaceutical Sustainability guidelines recommend life‑cycle reporting for high‑volume medicines.

Compliance is no longer optional - it affects market access and reputational risk.

Case Study: A Mid‑Size Manufacturer’s Turnaround

PharmaCo, a regional producer in Spain, faced criticism for high solvent emissions in its Irbesartan line. Over two years they:

- Switched from dichloromethane to ethanol, cutting VOC release by 70 %.

- Invested in a 1 MW solar array, supplying 45 % of the plant’s electricity.

- Implemented a closed‑loop water‑recycling system, reducing fresh‑water use from 2.5 m³ to 0.8 m³ per kg API.

The result? A 38 % drop in CO₂‑equivalent emissions and a 22 % cost saving on solvent purchases. The company earned a green‑manufacturing certification, opening doors to contracts with eco‑focused health systems.

What Patients and Prescribers Can Do

While the heavy lifting is on manufacturers, clinicians and patients can influence the chain:

- Prefer generics produced under green‑certified facilities - many European generics now carry a ‘sustainability badge.’

- Support waste‑take‑back programs that collect unused pills, preventing drug residues from entering waterways.

- Ask pharmacists about the origin of their medication; some chains disclose carbon‑footprint labels.

Collective demand can shift the market toward cleaner production.

Future Outlook: From Reactive to Proactive Sustainability

Emerging trends point to a greener horizon:

- Biocatalysis: Enzyme‑driven steps for heterocyclic construction could replace metal catalysts, slashing waste.

- AI‑guided synthesis: Machine‑learning models predict low‑impact pathways before a single vial is mixed.

- Decentralized micro‑factories: Small, modular plants near demand centers reduce transport emissions.

When these technologies mature, the next generation of Irbesartan/HCTZ tablets may have a footprint a fraction of today’s.

How much CO₂ is emitted during Irbesartan production?

Recent life‑cycle assessments estimate about 12.4 kg of CO₂‑equivalent per kilogram of Irbesartan API, mainly from solvent recovery and heat generation.

Can the environmental impact of Hydrochlorothiazide be reduced?

Yes. Switching to greener solvents like ethanol, recycling water, and using renewable energy for drying steps can cut CO₂ emissions by up to 30 % and halve solvent waste.

Are there regulations that force manufacturers to report environmental data?

In the EU, the EMA requires an Environmental Risk Assessment for new drug applications. The US FDA encourages voluntary reporting, and the WHO publishes sustainability guidelines that many companies follow.

What can I, as a patient, do to support greener drug manufacturing?

Ask your pharmacist about the source of your medication, choose generics from certified green manufacturers when possible, and participate in medication take‑back programs to prevent environmental contamination.

Will future Irbesartan/HCTZ pills be made using AI‑driven green synthesis?

Early pilots show promise. AI can suggest solvent‑free pathways and predict waste streams, but widespread commercial adoption is still a few years away as validation and regulatory acceptance progress.

Comments

Great rundown on the hidden footprint of our meds!

They don't tell you the real cost of those pills, but the truth is buried in the chemistry labs. Big pharma pushes these combos while ignoring the waste streams that choke our rivers. Every batch of Irbesartan/HCTZ spills solvents into the air, and who’s accountable? The regulatory loopholes let them sweep it under the rug. It feels like a secret pact with the fossil fuel industry.

i totally get why you’re rattled – the numbers in that LCA table are eye‑opening. we’re talking about dozens of kilograms of CO₂ just to make a kilo of API, which adds up fast when production scales. the solvent waste numbers aren’t just abstract; they end up in landfills or get incinerated, releasing VOCs. it's sad that many manufacturers still rely on NMP, a nasty solvent that’s hard to recycle. even small tweaks, like swapping to ethanol, can shave off a big chunk of that waste. honestly, the industry could do better if they listened to the science and public pressure. let’s hope these green‑certifications become a badge of honor, not a marketing gimmick. keep spreading the word, it matters.

The journey from raw material to a finished tablet is a saga of chemistry and engineering that most people never see. First the aromatic rings are forged from petro‑derived benzene, a process that already burns fossil fuels and releases greenhouse gases. Then comes the heavy use of solvents like NMP and dichloromethane which not only demand energy to recover but also pose health hazards to workers. Every batch requires heating, distillation and crystallisation steps that gulp down steam and electricity in huge volumes. The water footprint is staggering because each purification cycle spits out liters of wash water that must be treated before it can be released. Waste streams contain heavy metals and halogenated compounds that need special disposal, otherwise they contaminate soil and waterways. The life‑cycle assessments you cited make it clear that Irbesartan alone contributes over twelve kilograms of CO₂ per kilogram of API. When you add Hydrochlorothiazide the total climbs even higher, creating a combined impact that rivals other blockbuster drugs. Yet there are bright spots on the horizon, such as the adoption of continuous flow reactors that cut energy use by a third. Switching to greener solvents like 2‑MeTHF or ethanol can slash VOC emissions dramatically, sometimes by more than seventy percent. Catalyst recycling, especially for palladium, turns what used to be a toxic dump into a reusable resource. Water‑reuse loops using membrane bioreactors can bring fresh‑water consumption down to less than a kilogram per kilogram of API. Renewable energy integration, like rooftop solar farms, is already powering a fraction of the distillation columns in some plants. Companies that have embraced three or more of these strategies report up to forty percent reductions in carbon footprints. The regulatory push from the EMA and FDA is nudging the industry, but voluntary initiatives often move faster than law. In the end, the combination of technology, policy and consumer demand will decide whether future Irbesartan/HCTZ tablets are greener than today.

Let’s keep the momentum going – every small improvement in a plant adds up to a healthier planet for all of us.

Indeed, the data are compelling, and they illustrate how intertwined manufacturing choices, energy sources, and solvent selections truly are, which means that any single change can ripple through the entire lifecycle, reducing emissions, waste, and costs simultaneously.

Yo, it’s wild how much carbon we pack into a tiny pill, and I’m hopeful that with newer tech we’re gonna see a huge drop in that footprint.

I appreciate the thorough breakdown; it really helps stakeholders see where the biggest environmental gains can be made.

Absolutely, and sharing these success stories inspires other manufacturers to adopt similar green steps.

Wow, this is eye‑opening! 🌍💊 Let’s push for greener meds everywhere! 👍

Eco‑friendly drugs are the future.

The integration of renewable energy sources into pharmaceutical production not only aligns with regulatory expectations but also offers long‑term economic benefits.

Green chemistry wins.

Let’s stay hopeful and keep championing sustainable pharma!